Joseph A. Incavo

Experienced Tire Expert Witness

|

Dr. Joseph Incavo provides expert consulting in science and technology of polymeric materials, rubber and tires. He has in-depth experience in various aspects of consumer rubber products including materials and compounding, chemical and mechanical analysis, product testing, quality processes and FEA modeling. His experience of 30+ years spans from real-world product and manufacturing processes to the application of fundamental first principles. He has participated in many litigations as a tire expert witness.

|

Education

Ph.D., Analytical Chemistry, Ohio State University, Columbus, Ohio, 1989

B.A., Chemistry, College of Wooster, Wooster, Ohio, 1983

Experience

Expert Consulting

Expert Consulting, Baldwin v. Sumitomo Rubber Industries In depth chemical and materials analysis of failed tire innerliners, including issuing protocols, declarations, detailed technical reports. US District Court of New Hampshire, Settled April 2023

Expert Witness, Trydel Research vs. ITW Global Tire Repair, Declarations filed in US Patent and Trademark Office Before the Patent Trial and Appeal Board, Patent invalidation research, declaration and deposition, February 2020.

Expert Consulting, Overton vs. Michelin North America et. al. Materials analysis of failed tire including issuing protocols, declarations, chemical and mechanical analysis. Settled in Superior Court of the State of California, Los Angeles Co. April 2020.

Expert Witness, Cunningham vs. Bridgestone Americas Tire Operation; Chemical analysis of foreign material and tire rubber chemicals; Deposition in 394th Judicial District of Texas, December, 2017

Expert Consulting, Cosby vs. Kumho Tire Co Inc. et. al., Innerliner analysis and tire failure analysis. District Court of Angelina Co., TX, April 2018.

Expert Consulting, Stryker Vehicle Tire Analysis, Root cause analysis of tire damage involving shipping and field usage. March 2017

Expert Consulting, Barralaga vs. Cooper Tire et al, Tire failure analysis, test protocol creation, prior art and documentation review. November, 2019

Expert Witness, Corey Butler v. Cooper Tire et al, Tire Finite Element Analysis, Deposed in case filed in US District Court Southern District of Georgia. December, 2014

Expert Consulting, Foscini et al v. Bridgestone Corporation et al, Tire Finite Element Analysis, case settled in mediation. Pennsylvania Eastern District Court. March, 2014.

HMH / Baker Hughes, Technical Center, Houston, TX

Engineering Director, Seals & Materials Center of Excellence, 10/2017-present

Direct and manage team in design, construction, testing, qualification and manufacturing of elastomer seal products. Combine leading a team of engineers/scientists with supplying deep domain technical expertise to deliver on business objectives. Establish goals and direction for sustaining as well as R&D projects with full accountability for delivering on set goals. In directing a cross-functional team, apply experience in rubber compounding and manufacturing together with hyperelastic FEA modeling, large-scale component testing and customer/field issues. Chair API elastomer committee for standards in drilling in the oil and gas industry.

Argen Polymer LLC, Cypress, TX, 1/2014-10/2017

Technical Director, Directed chemical and physical test programs for clients in oil & gas, chemical, food/beverage and transportation industries. Secured and executed large-scale joint development programs between various exploration and service oil & gas companies. Designed, tested and qualified advanced rubber compounds for next generation high temperature/high pressure drilling.

GE Oil & Gas, Hydril Technical Center, Houston, TX

Senior Control Title Engineer, 2011–2014. Designed and commercialized new elastomer seals used in blow out preventers (BOPs). Advised as elastomer materials and technology expert across GE. Gained broad experience in formulation, predictive lab testing and large scale testing of oil & gas non-metallics including NBR, HNBR, FKM, FFKM elastomers.

The Goodyear Tire & Rubber Company, Technical Innovation Center, Akron OH

Program Leader, 2010-2011

Led an advanced concept tire program composed of novel materials and designs including schedule, budget and meeting technical targets.

Lead Compounder, 2007-2010

Ownership responsibility for innerliner, sidewall, tread compounds worldwide. Developed and commercialized new tire products such as Duraseal, RFID truck tires, improved tread, sidewall and innerliner compounds.

Gained in-depth experience in tire manufacturing including:

Gained in-depth experience in tire testing and product release including:

Associate Scientist, 2000 – 2007

Senior Research Chemist, 1996-2000

Invented new analytical methodologies for tire and rubber product failure analysis. Led programs using broad suite of analytical methods. Conceived and implemented novel sensor system leak detection in tire curing process achieving multi-million dollar manufacturing cost savings.

In-depth experience in forensic techniques including:

OxyChem / Lyondell Chemical, Corporate Technology Center, Grand Island, NY

Senior Research Chemist, 1994-1996

Research Chemist, 1991-1994

Team leader of R&D and plant support projects. Provided analytical support of petrochemicals including polyethylene, butadiene, feedstocks for hydrocracking, vinyl chloride, ethylene dichloride, hexane drying of polymers.

Supervisor of analytical lab for specialty products including chlorinated chemicals, petrochemical feedstocks. Developed multi-dimensional gas chromatography methods for complex analyses. Implemented process analytical methods for production control.

Praxair / Union Carbide Industrial Gases, Technology Center, Buffalo, NY

Staff Chemist, 1989-1991, Developed gas analysis methods for toxic gases and cryogenic gases. Presented product and technical information to customers.

Awards, Memberships

Ph.D., Analytical Chemistry, Ohio State University, Columbus, Ohio, 1989

B.A., Chemistry, College of Wooster, Wooster, Ohio, 1983

Experience

Expert Consulting

Expert Consulting, Baldwin v. Sumitomo Rubber Industries In depth chemical and materials analysis of failed tire innerliners, including issuing protocols, declarations, detailed technical reports. US District Court of New Hampshire, Settled April 2023

Expert Witness, Trydel Research vs. ITW Global Tire Repair, Declarations filed in US Patent and Trademark Office Before the Patent Trial and Appeal Board, Patent invalidation research, declaration and deposition, February 2020.

Expert Consulting, Overton vs. Michelin North America et. al. Materials analysis of failed tire including issuing protocols, declarations, chemical and mechanical analysis. Settled in Superior Court of the State of California, Los Angeles Co. April 2020.

Expert Witness, Cunningham vs. Bridgestone Americas Tire Operation; Chemical analysis of foreign material and tire rubber chemicals; Deposition in 394th Judicial District of Texas, December, 2017

Expert Consulting, Cosby vs. Kumho Tire Co Inc. et. al., Innerliner analysis and tire failure analysis. District Court of Angelina Co., TX, April 2018.

Expert Consulting, Stryker Vehicle Tire Analysis, Root cause analysis of tire damage involving shipping and field usage. March 2017

Expert Consulting, Barralaga vs. Cooper Tire et al, Tire failure analysis, test protocol creation, prior art and documentation review. November, 2019

Expert Witness, Corey Butler v. Cooper Tire et al, Tire Finite Element Analysis, Deposed in case filed in US District Court Southern District of Georgia. December, 2014

Expert Consulting, Foscini et al v. Bridgestone Corporation et al, Tire Finite Element Analysis, case settled in mediation. Pennsylvania Eastern District Court. March, 2014.

HMH / Baker Hughes, Technical Center, Houston, TX

Engineering Director, Seals & Materials Center of Excellence, 10/2017-present

Direct and manage team in design, construction, testing, qualification and manufacturing of elastomer seal products. Combine leading a team of engineers/scientists with supplying deep domain technical expertise to deliver on business objectives. Establish goals and direction for sustaining as well as R&D projects with full accountability for delivering on set goals. In directing a cross-functional team, apply experience in rubber compounding and manufacturing together with hyperelastic FEA modeling, large-scale component testing and customer/field issues. Chair API elastomer committee for standards in drilling in the oil and gas industry.

Argen Polymer LLC, Cypress, TX, 1/2014-10/2017

Technical Director, Directed chemical and physical test programs for clients in oil & gas, chemical, food/beverage and transportation industries. Secured and executed large-scale joint development programs between various exploration and service oil & gas companies. Designed, tested and qualified advanced rubber compounds for next generation high temperature/high pressure drilling.

GE Oil & Gas, Hydril Technical Center, Houston, TX

Senior Control Title Engineer, 2011–2014. Designed and commercialized new elastomer seals used in blow out preventers (BOPs). Advised as elastomer materials and technology expert across GE. Gained broad experience in formulation, predictive lab testing and large scale testing of oil & gas non-metallics including NBR, HNBR, FKM, FFKM elastomers.

The Goodyear Tire & Rubber Company, Technical Innovation Center, Akron OH

Program Leader, 2010-2011

Led an advanced concept tire program composed of novel materials and designs including schedule, budget and meeting technical targets.

Lead Compounder, 2007-2010

Ownership responsibility for innerliner, sidewall, tread compounds worldwide. Developed and commercialized new tire products such as Duraseal, RFID truck tires, improved tread, sidewall and innerliner compounds.

Gained in-depth experience in tire manufacturing including:

- Mixing of tire compounds

- Calendaring, extrusion and processing of belt and ply treatments

- Automated and manual tire building

- Tire curing, thermocoupling and butyl bladder conditions

- Tire inspection, final finish and leak detection

Gained in-depth experience in tire testing and product release including:

- FMVSS119, FMVSS139 tire test standards

- Durability and high speed wheel testing

- Pressure retention and air permeation tire testing

- Puncture sealing tire testing

- Fleet testing of radial medium truck tires

- Global requirements for product qualification and release

- Monitoring and reporting of field adjustment conditions

- Mitigation and resolution of field conditions

Associate Scientist, 2000 – 2007

Senior Research Chemist, 1996-2000

Invented new analytical methodologies for tire and rubber product failure analysis. Led programs using broad suite of analytical methods. Conceived and implemented novel sensor system leak detection in tire curing process achieving multi-million dollar manufacturing cost savings.

In-depth experience in forensic techniques including:

- Halobutyl innerliner analysis

- Baby-bottle rubber nipples and other rubber products

- Rubber fuel hoses

- Rubber automotive belts and conveyor belts

- Innerliner condition and permeability characteristics

- Rubber compound reformulation

- Oxidation of tire beltcoat and carcass compounds

- Thermo-oxidative degradation of tire compounds

- Rubber-to-metal bonding

- RFL ply dips and adhesion

- Volatiles analysis and tire hydrocarbon emissions

OxyChem / Lyondell Chemical, Corporate Technology Center, Grand Island, NY

Senior Research Chemist, 1994-1996

Research Chemist, 1991-1994

Team leader of R&D and plant support projects. Provided analytical support of petrochemicals including polyethylene, butadiene, feedstocks for hydrocracking, vinyl chloride, ethylene dichloride, hexane drying of polymers.

Supervisor of analytical lab for specialty products including chlorinated chemicals, petrochemical feedstocks. Developed multi-dimensional gas chromatography methods for complex analyses. Implemented process analytical methods for production control.

Praxair / Union Carbide Industrial Gases, Technology Center, Buffalo, NY

Staff Chemist, 1989-1991, Developed gas analysis methods for toxic gases and cryogenic gases. Presented product and technical information to customers.

Awards, Memberships

- Baker Hughes Corporate Engineering Award – Best Manufacturing Excellence – 2020

- Baker Hughes Corporate Engineering Award – Collaboration Excellence - 2019

- Chair of American Petroleum Industry (API) work group committee 2021

- Baker Hughes General Electric Corporate Engineering Award – Best Manufacturing Excellence - 2018

- General Electric Corporate Engineering Award, 2013

- Role Model rating as Control Title Engineer, 2013

- Goodyear Corporate Inventor of the Year Award, 2002

- Goodyear Chairman’s Award, 2001

- Six Sigma Green Belts, Instructor of Six Sigma and Quality Systems

- ASTM Committee Member (American Society of Testing Materials)

- RMA Committee Member (Rubber Manufacturers Association)

- API Committee Chair (American Petroleum Industry)

- Tire Society Member

- American Chemical Society Member

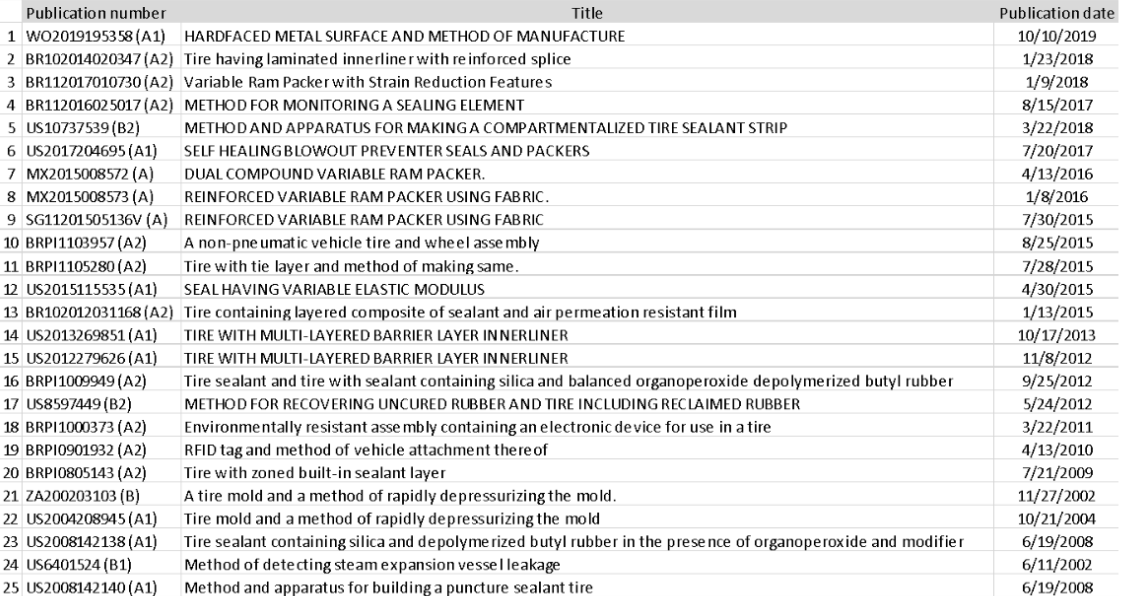

Patents and Publications

- Molecular Simulations and Experimental Characterization of Fluorinated Nitrile Butadiene Elastomers with Low H2S Permeability

- SIMPLIFIED METHOD FOR THE DETERMINATION OF N-NITROSAMINES IN RUBBER VULCANIZATES; INCAVO, J.A., SCHAFER, M.A. 2006 ANALYTICA CHIMICA ACTA 557 (1-2), PP. 256-261

- INVESTIGATION OF POLYIMIDESILOXANES FOR USE AS ADHESIVES BY ELECTRON SPECTROSCOPY FOR CHEMICAL ANALYSIS; ZHUANG, H., GARDELLA JR., J.A., INCAVO, J.A., ROJSTACZER, S., ROSENFELD, J.C. 1997 JOURNAL OF ADHESION 63 (1-3), PP. 199-214

- INVESTIGATION OF HEXANE DIFFUSION IN HDPE PARTICULATES FOR DRYING APPLICATIONS; QI, J.S., KRISHNAN, C., INCAVO, J.A., JAIN, V., RUETER, W.L. 1996 INDUSTRIAL AND ENGINEERING CHEMISTRY RESEARCH 35 (10), PP. 3422-3430

- DETERMINATION OF PARTITION COEFFICIENTS AND RESIDUAL SOLVENT FOR POLYMER DRYING APPLICATIONS, INCAVO, J.A., JAIN, V., QI, J.S., KRISHNAN, C. 1996 CHROMATOGRAPHIA 43 (1-2), PP. 31-38

- A DETAILED QUANTITATIVE STUDY OF 1,2-DICHLOROETHANE CRACKING TO VINYL CHLORIDE BY A GAS CHROMATOGRAPHIC PYROLYSIS DEVICE; INCAVO, J.A. INDUSTRIAL AND ENGINEERING CHEMISTRY RESEARCH 35 (3), PP. 931-937, 1996

- ZEOLITE HOST-GUEST INTERACTIONS: OPTICAL SPECTROSCOPIC PROPERTIES OF TRIS(BIPYRIDINE)RUTHENIUM(II) IN ZEOLITE Y CAGES; INCAVO, J.A., DUTTA, P.K. 1990 JOURNAL OF PHYSICAL CHEMISTRY 94 (7), PP. 3075-3081 49.

- PHOTOELECTRON TRANSFER FROM TRIS(2,2-BIPYRIDINE)RUTHENIUM(II) TO METHYLVIOLOGEN IN ZEOLITE CAGES: A RESONANCE RAMAN SPECTROSCOPIC STUDY; DUTTA, P.K., INCAVO, J.A. 1987 JOURNAL OF PHYSICAL CHEMISTRY; 91 (17), PP. 4443-4446.

- Vibrational Spectra, Including Matrix Isolation and Conformations of 1,1,2-Trichloro-2,3,3-Trifluorocyclobutane, Gatial, A., Klaeboe, P., Nielsen, C., Sablinskas, V., Powell, D.,Kondow, A., Incavo, J., JOURNAL of Molecular Structure, 295(73) 1993.